In this section I’m documenting other neglected snagging jobs and poor workmanship.

Follow the link below to the snagging report carried out by DB & PAUL of Wells in November 2022.

This report, along with two others was sent to the developer and builder and alerted me to the problems with the build.

Project management…Machiavellian in concept…the developer sold an unfiinshed house, delivered 9 months late.

The builder used EPDM to clad the stand wall; it has blistered and bubbled over the year since I moved in. EPDM is used as the waterproof membrane for green roofs…The architects spec requested metal cladding from TATA steel…

Image below; water pooling on the dormer window roofs

The cladding trim buckles in hot weather…and is not the correct finish.

The builder used random soffit material.

Cracked and damaged guttering…indicating a problem with all the guttering around the house; which remains a big issue…there are not enough, or poorly positioned brackets and the downpipes detach from the swan necks in windy weather and it will need very expensive scaffolding to gain access to the gutters to replace and repair.

The dameged guttering and tile was caused by a digger banging in to that area during the build process. Yet nobody sought to repair this. I have made numerous requests for this situation to be remedied.

Broken roof tile (above) repaired with a piece of hard plastic sheet (by me) to stop water spraying down onto the balcony

Kitchen counter…replaced at my expense. Badly scratched and poorly repaired with a tipex type material… the corner trim ill fitting, sharp and dangerous; particularly for children of a certain height.

The developer has refused to remedy this issue and all the others documented on this website.

This, despite three kitchen counter measurng visits by those resposible for this work who both accepted that there was a problem with the counter…and, as ever, nothing was done.

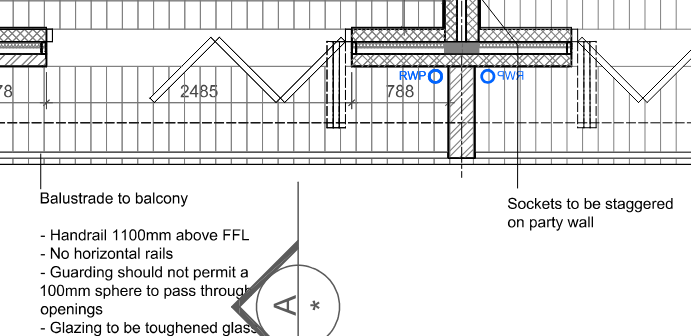

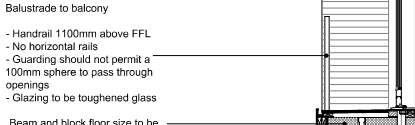

The decking is cracked in two places; which is very worrying…the balustrade does not have a securing bracket; wobbling dangerously in heavy wind…and the layout and measurements of the whole balcony are ill conceived with one small panel at the very end in the wrong position; it should be at the centre of the structure along with the mentioned securing bracket. Only two of the shoes holding the glass on the end panel are functioning…(now replaced by me).

Balcony boards cut in half horizontally to fit with the bi-fold door because measurements are wrong…or the builder ran out of boards

It seems that the balcony had to be extended outwards to accomodate the outward opening bi-fold doors, which is the reason there is no securing of the balustrade into the ‘party’ brick wall separating the two houses as illustrated in the plans and the image used to sell the property on Rightmove…

Images below show damaged decking.

Bi-fold door too wide…The grey steel joist with holes drilled should support the balustrade along its length and then be secured into the redbrick buttress…

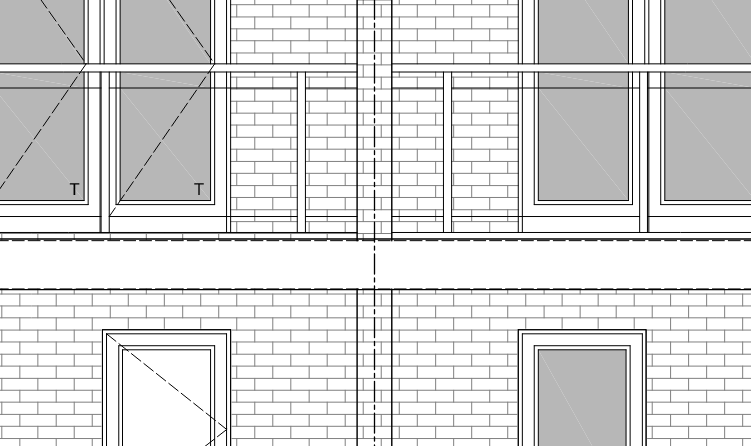

see detail from architects plans below…clearly showing that the toprail of the balustrade should be fixed into the brick buttress.

Water egress from the balcony during one of the Autumn storms…Ciaran I think…

The tarp prevents the water percolating through the blocks on the drive, onto the concrete foundation raft and into the house.

The concrete raft below the blocks slopes into the houe by “half a bubble at least” when checks were done using a spirit level… I have laid the Tarp over the forecourt to prevent the water damaging the house further.

The recalcitrant end panel(below)

Image below shows where the small end panel should be…in the centre of the structure along with a securing bracket attached to the wall shown below…or housed in the sides of the brick party wall…oops, if that was done according to the plans, the bi-fold door would not open properly.

The images below indicate how much the balcony had to be extended outwards to accomodate the bi-fold doors above – which would not open otherwise – and also explains why the balustrade is not secured in the side of the party wall as specified by the architects plans. The builder dismissed our initial fears by declaring “you don’t know what you’re talking about”.

The small movie below indicates the precarious nature of the balustrade.

Everything to the left of the steel joist represents just how far the balcony was extended outwards…

The balcony decking has been replaced now; to prevent further water damage.

The whole of the “unseen” elevations of the house are not rendered or painted; revealing raw and very absorbent concrete blocks.

The mortar between the blocks is poorly finished with gaps and “snot” aplenty…

Should these walls have been rendered or painted?

The black strip along the base of the wall is bitumen paint applied by the builder in May 2023. I offer this information without comment, other than “why?”

Images above and below showing the extent of the poorly engineered balcony running left to right high to low and into the house. The concrete “tongue” visible above the decking is level…and the balcony slopes, I am told, front to back, by 250mm.

29/12/23

A Christmas water leak. More water leaks from the poorly fitted pipes.

Walls and ceilings ruined below.

The garage door frame is not square. 25mm out… top to bottom and may explain the extreme difficulty opening and closing it.

The garage door represents a big security risk. It is hard/impossible to lock, and if anybody accesses the garage then it easy to break into the house from inside this space.

The garage door will have to be replaced…

The image below shows a crack developing in the outside wall leading to the balcony.

On the other side of the wall corresponding with this crack are the stairs up to the house and the balcony. This wall is only one concrete block wide. I have taken some advice from local trades and the consensus is…”knock it down and re-build it using concrete blocks laid width wise rather tha the very unstable length option used here”

Penny pinching or nickel and diming; call it what you will. This wall will not stand the test of time.

Where on earth were Stroma the building control company assigned to check all stages of the build to confirm that all the regulations were being complied with.

I have only one inspection report from the whole of the bulding process and, as you might expect, the final completion certificate. Both signed by a Mr Richard Serrel, at the Watford branch of the company. He has never returned my calls.

Further, apart from the stairs up, the construction is under pressure from the adjacent subsidence

The Aco drain is not connected to the drains and soakaway system. The water from the Aco is eroding the sand beneath the pavers on the drive as it leaks and percolates down the slope.